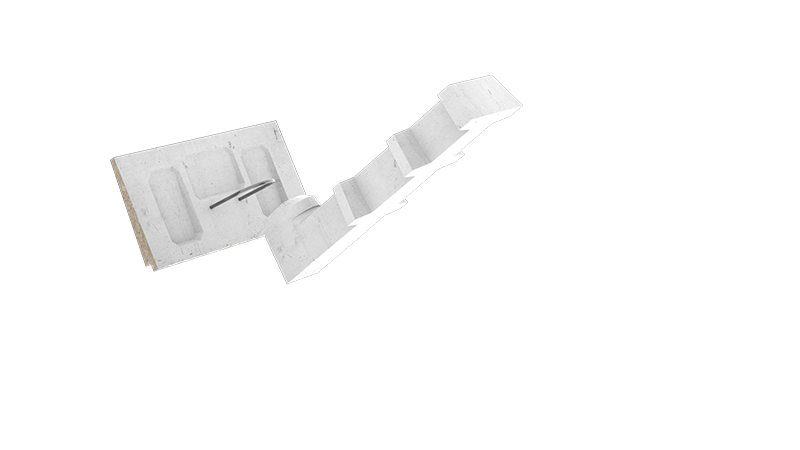

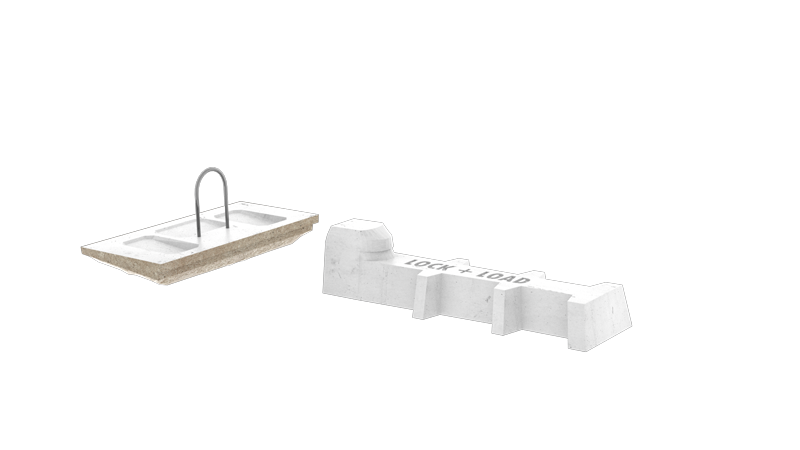

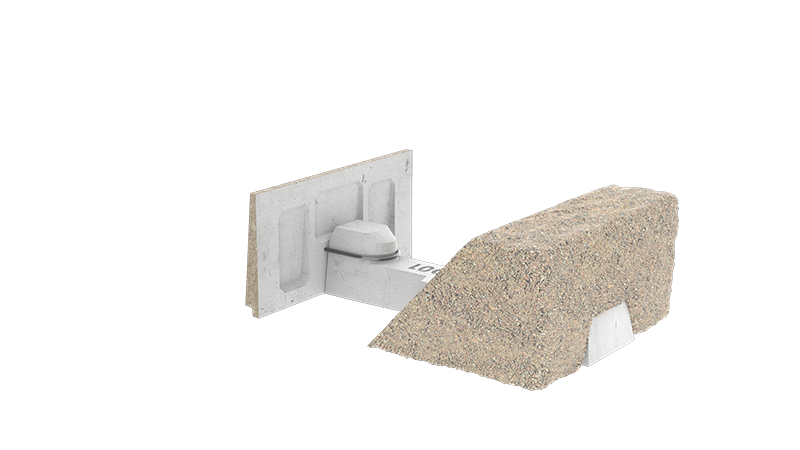

LOCK+LOAD supports earth retention using the standard design concept of a cantilever. The panel and counterfort sections when combined create the LOCK+LOAD Cantilever Unit. Each LOCK+LOAD unit stabilizes a block of compacted soil, in essence creating a self-stabilized soil block with a concrete face.

The LOCK+LOAD retaining wall solution was developed to take advantage of the self-weight of soil to restrain horizontal loads from that same soil. The weight of soil mass being 3 times greater than the resultant horizontal thrust from the same soil. The Cantilever Units are proportioned to take full advantage of these forces. ensuring the horizontal soil load is never exceeded.

The Cantilever Units are independently deployed and are supported only by the surrounding soil.

This individuality allows for installation of LOCK+LOAD walls in almost any configuration: level or on grade, battered or vertical, curved or straight, and potentially all in the same wall.

Long term performance of LOCK+LOAD comes from simple, independent cantilevers, constructed of high quality cast concrete, utilized in a low stress soil environment.

LOCK+LOAD allows for a single zone of uniform compaction of backfill up to the back of the wall panel.

The LOCK+LOAD Cantilever Unit is independent, so the concrete parts do not stack on one another, allowing any elastic compression of the backfill to be absorbed without stress. This elastic compression takes place in all walls and is relatively minor, less than 1%. The LOCK+LOAD solution is great at responding to any and all potential soil compression since Cantilever Units are completely independent and individually stable.

The slender panel design of the Cantilever Units maximize land use and accommodate fences or barriers right at the wall face due to their strength, as demonstrated by resisting the compaction of the backfill.

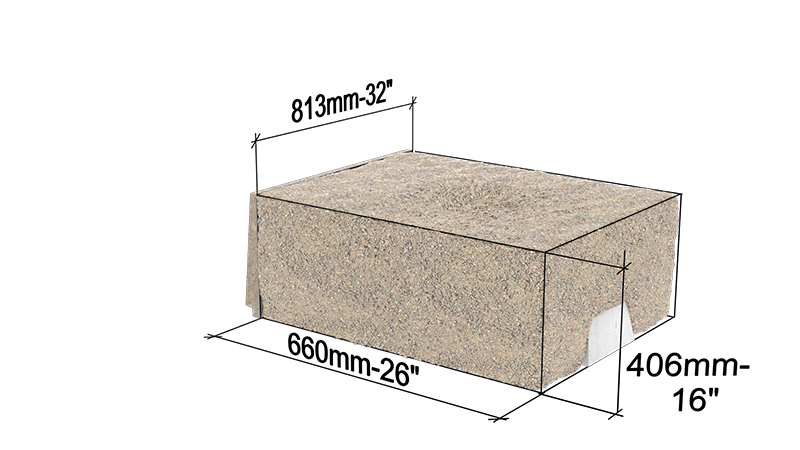

LOCK+LOAD is comprised of a panel (90lbs) and counterfort (40lbs). The Unit is manufactured utilizing wet cast, air-entrained, fiber and steel reinforced, 5500 psi (38 Mpa) concrete. Shipping is done on pallets, each pallet holding 14 units, weighing approximated 1850 lbs and providing about 50 square feet of wall face (4.6sqm).

Without additional soil reinforcement, LOCK+LOAD is considered a gravity structure that can be used to create walls 4 rows or 5’ 4” (1.6 m) high. Taller walls require the Cantilever Units to act as a stabilized soil facing for a larger reinforced soil structure such as : Mechanically Stabilized Earth (MSE), Geosynthetic Reinforced Soil (GRS), Soil Anchors and Nails. LOCK+LOAD installation remains virtually the same, as only the additional soil reinforcement may vary in length, type and location. Since Cantilever Units are independent there is no vertical accumulation of stress.

These LOCK+LOAD walls behave as a true Mechanically Stabilized Soil Mass with non-extendiable reinforcement using common MSE analysis methods.

Design information required to consider the LOCK+LOAD Solution

Strength of Panel to Counterfort – Lock+Load Cantilever Unit Strength

Strength of Counterfort to Soil – Lock+Load Cantilever Unit Embedment Strength

Strength of Set connection to Reinforcement – Connection Strength Grid Over Lock+Load Units

The design and test verification of various product elements is attached in the Specification sheets. Concrete Strength and characteristics, steel composition, component verifiable capacities, connection strength and durability testing are some of the extensive information available.

LOCK+LOAD promotes the use of MSEW provided by Adama Engineering for standardized MSEW design approach. LOCK+LOAD will be happy to assist and please forward any specific Engineering requests that are not covered in the attachments to the following: info@lock-load.com